From winemakers

to winemakers

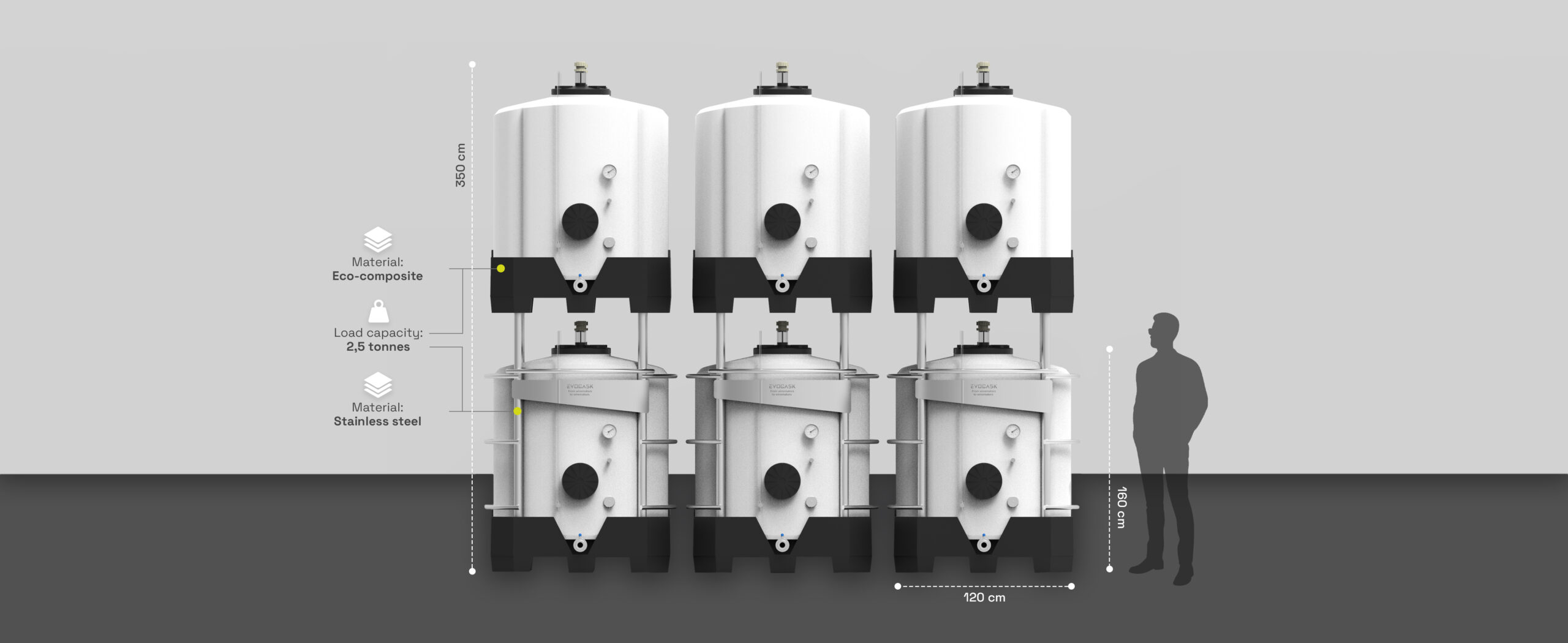

6 and 11 hl EvoCask models available

in Europe from June 2024!

Reduce your costs

Less barrel and labour costs, better use of space in the cellar. EvoCask is a long-term investment that does not need to be replaced every three years. With proper maintenance, it will still be as high quality in 20 years as it was in the early days.

Protect our environment

The EvoCask maturation tank works with insert bins. These oak staves are more environmentally friendly than traditional barrels, as they can give the same result with less wood use. You can therefore significantly reduce the ecological footprint of your winery.

Adapt to your needs

A Cabernet Sauvignon aged in oak barrels will have excellent flavours, but a Riesling does not always require the same. The EvoCask offers a unique flexibility, ensuring optimal oxygenation for ageing for all types of wine. This cannot be achieved with stainless steel tanks.

Maturing with 21st century technology

From winemakers to winemakers

The EvoCask wine tank is a maturation tank designed for winemakers, manufactured with an eco-composite formula that provides controlled oxygen permeation. The 21st century technology allows the tank to be both easy to clean and modern in appearance, with maximum space utilisation and environmentally friendly solutions. Our aim is to enable wineries to operate with less work, less risk and in a cost-effective way.

Step into the 21st century and take full advantage of the EvoCask wine container.

1. eco-composite formula

2. cleanability,

use of space

3. controlled oxygen permeability

Eco-composite Formula: an innovative and durable solution for the winery

Oxygen permeation and food safety.

Controlled oxygen transfer to ensure wine maturation, similar to oak barrels, developed for the food industry.

Long life span

Can be used for up to 30-50 years, compared to 2-5 years for oak barrels.

Environmentally friendly solution

Can be recycled, reducing environmental impact.

Hygiene

Non-porous surface, less prone to accumulation of dirt and microorganisms.

Easy maintenance and manageability

Easy to clean, light weight, easy to move and long-lasting usability.

Cost-effectiveness

A more economical solution due to longer life and lower maintenance requirements.

Versatility in the winery

Flavour neutrality, allowing the winemaker to develop the desired flavour profile using other methods.

Temperature Resistance

Excellent for temperature fluctuations encountered in winemaking (up to -40-80°C)

Acid and Alkaline Resistance

Excellent acid and alkaline resistance, allowing safe storage of a variety of wines without damaging the material.

Mechanical properties

High impact resistance (Izod test: 20-30 kJ/m²) and flexibility, which protects the container from physical damage and ensures durability.

Thermal Conductivity Coefficient

0.38 W/mK, which ensures good thermal insulation, minimising the effect of temperature fluctuations on the quality of the wine.

Tensile strength

25-30 MPa, which ensures the durability of the material and its resistance to mechanical stress.

Density

0,945 to 0,965 g/cm³, which gives a density of

About production

The EvoCask containers we produce for wineries are manufactured using rotational moulding technology. This is a very special technology as injection moulding of large food products is extremely expensive or not possible at all.

Some facts about rotational moulding

Rotational moulding is a plastic moulding technique that uses heat and rotational force to mould hollow objects. This versatile technology can be used to produce a wide range of products, including pots and containers of various sizes and shapes, beverage, food and medical containers, as well as drinking water and a variety of agricultural uses. In the process, plastic powder is heated in a mould until it melts, takes the shape of the mould and is then cooled. The mould is rotated throughout the heating and cooling process to evenly distribute the wall thickness of the piece.

Why is Evocask the best solution?

Steel tank

wooden barrel

Evocask

IBC tank

Lifetime, durability

High

Low

High

Medium

Air permeability

None

Variable

Optimal

Too high

Risk of infection

None

Yes

None

Yes

Cleanability

Easy

Steel tanks have all the positive qualities of a good value, as long as fresh, reductive wine is the goal. However, optimum oxygen intake is needed to mature the wine, which can only be achieved with very expensive technology, and the potential for error is very high compared to passive ageing.

Heavy

The challenges of cleaning wooden barrels are that their porous structure starts to clog as soon as wine is poured into them, so cleaning them thoroughly is time-consuming and requires special tools and techniques, and they lose their oxygen permeability almost completely after the third filling. And the risk of contamination is always a risk to be reckoned with.

Easy

The Evocask wine container’s smooth, curved interior surfaces and spacious openings allow all parts to be easily accessible, cleaned quickly and thoroughly, and the last drop to spill out. After each cleaning, the original oxygen permeability, optimal for ageing wines, is restored. And with oak staves, the winemaker can decide how much wood flavour he or she wants, or even show the true, matured face of the wine without the wood segments.

Heavy

Cleaning IBCs is problematic because the rectangular shape makes it difficult to reach the corners and the bottom is flat, making it almost impossible to empty them completely even when tilted. The support frame is usually galvanised, and even minor damage will start corrosion. The much higher oxygen permeability makes them unsuitable for wine ageing.

Why is Evocask the best solution?

IBC tank

Lifetime, durability

Medium

Air permeability

Too high

Risk of infection

Yes

Cleanability

Heavy

Cleaning IBCs is problematic because the rectangular shape makes it difficult to reach the corners and the bottom is flat, making it almost impossible to empty them completely even when tilted. The support frame is usually galvanised, and even minor damage will start corrosion. The much higher oxygen permeability makes them unsuitable for wine ageing.

Wooden barrel

Lifetime, durability

Low

Air permeability

Variable

Risk of infection

Yes

Cleanability

Heavy

The challenges of cleaning wooden barrels are that their porous structure starts to clog as soon as wine is poured into them, so cleaning them thoroughly is time-consuming and requires special tools and techniques, and they lose their oxygen permeability almost completely after the third filling. And the risk of contamination is always a risk to be reckoned with.

Evocask

Lifetime, durability

High

Air permeability

Optimal

Risk of infection

None

Cleanability

Easy

The Evocask wine container’s smooth, curved interior surfaces and spacious openings allow all parts to be easily accessible, cleaned quickly and thoroughly, and the last drop to spill out. After each cleaning, the original oxygen permeability, optimal for ageing wines, is restored. And with oak dongles, the winemaker can decide how much wood flavour he or she wants, or even show the true, matured face of the wine without the wood segments.

Steel tank

Lifetime, durability

High

Air permeability

None

Risk of infection

None

Cleanability

Easy

Steel tanks have all the positive qualities of a good value, as long as fresh, reductive wine is the goal. However, optimum oxygen intake is needed to mature the wine, which can only be achieved with very expensive technology, and the potential for error is very high compared to passive ageing.

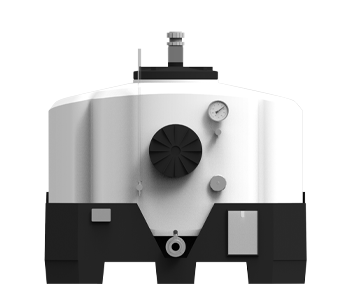

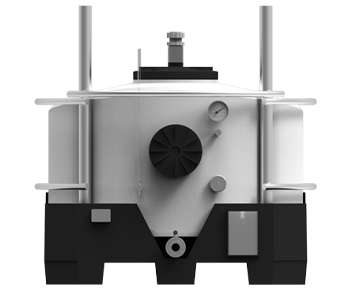

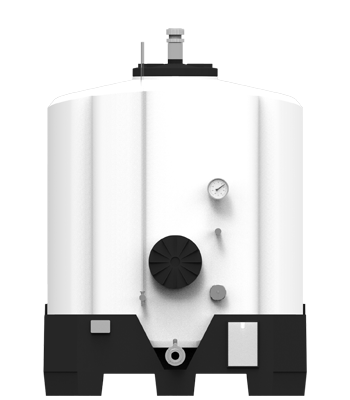

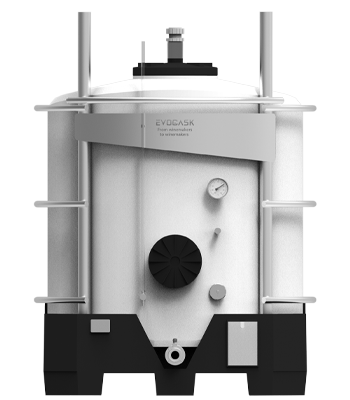

Our products

Model 6 sur lie

600 liter

Model 6 sur lie R

600 liter

Model 11

1100 liter

Model 11 R

1100 liter

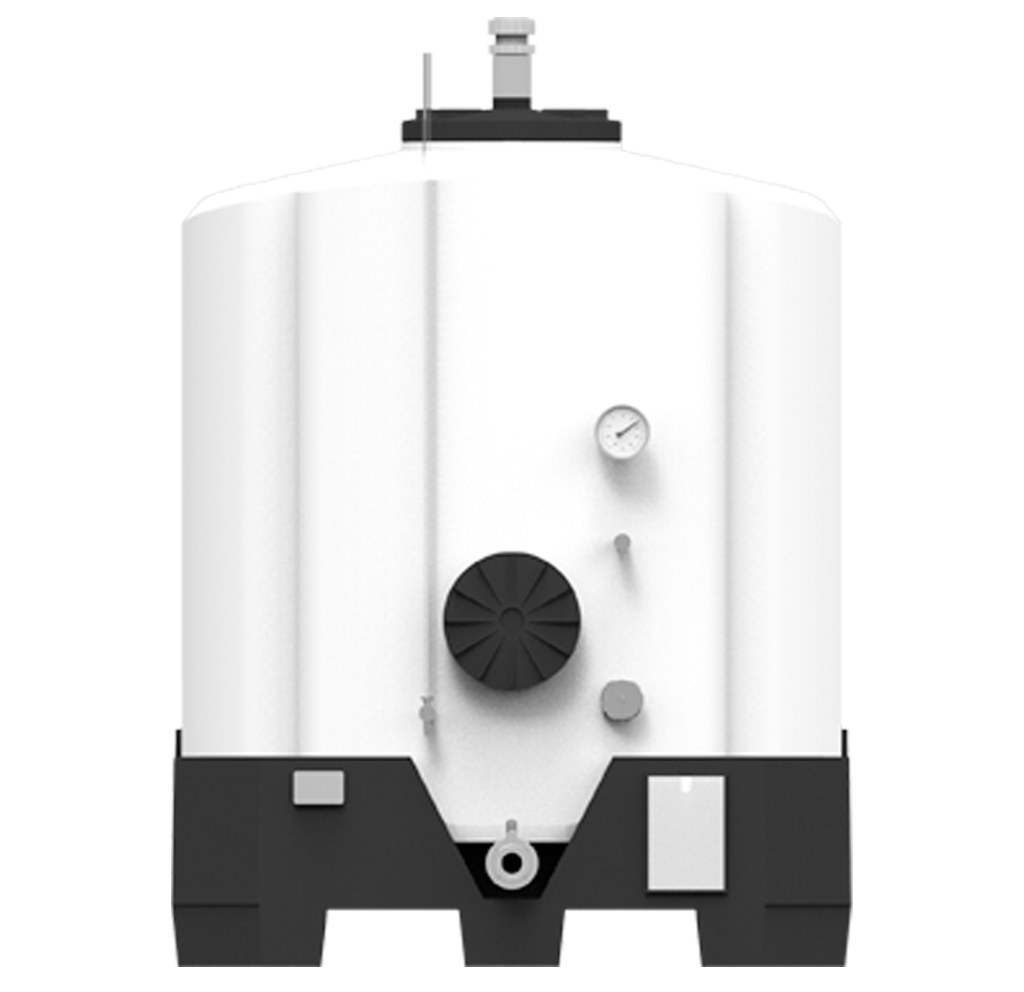

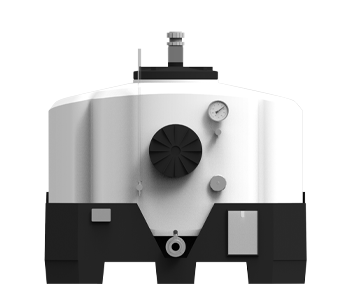

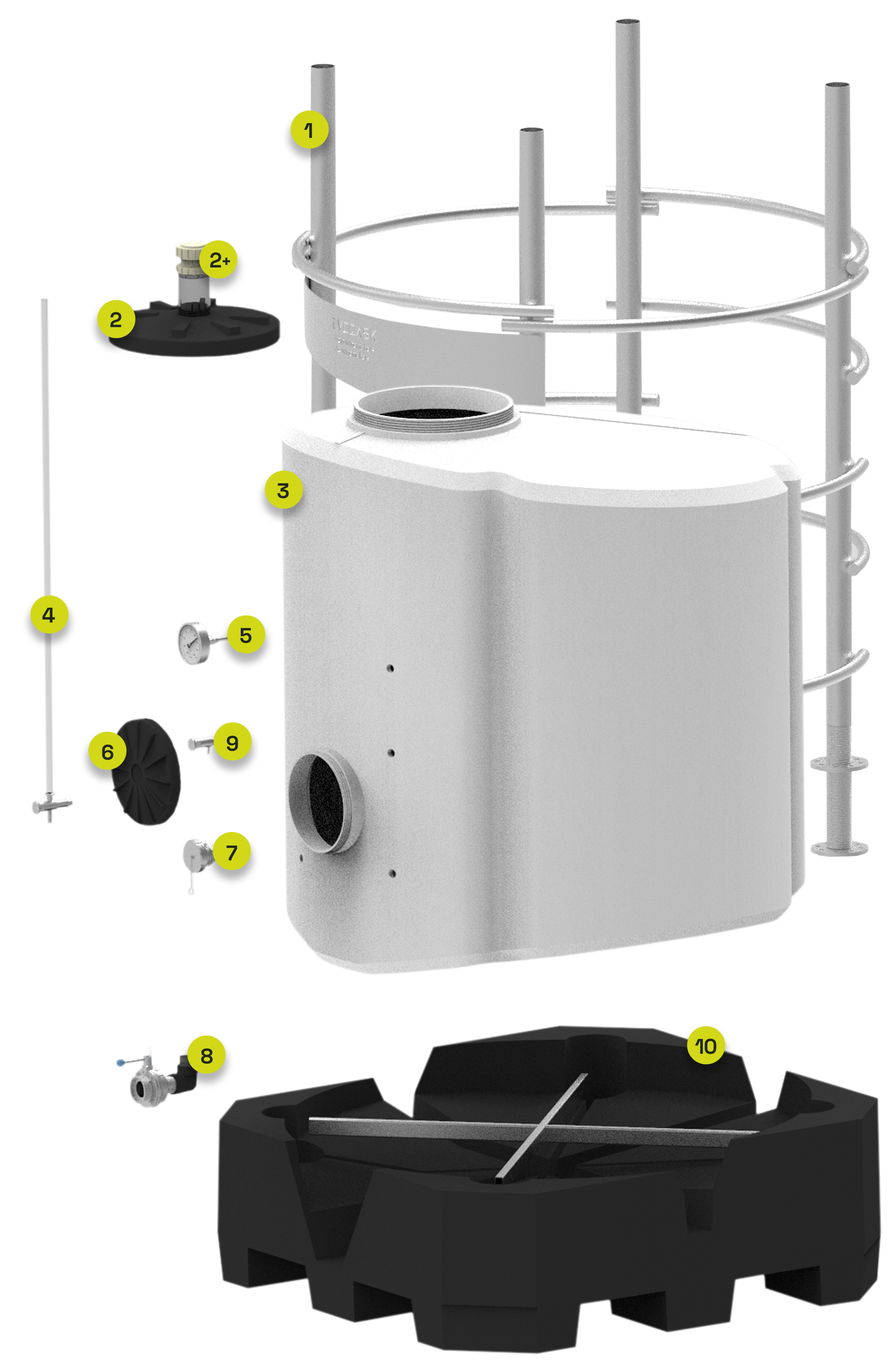

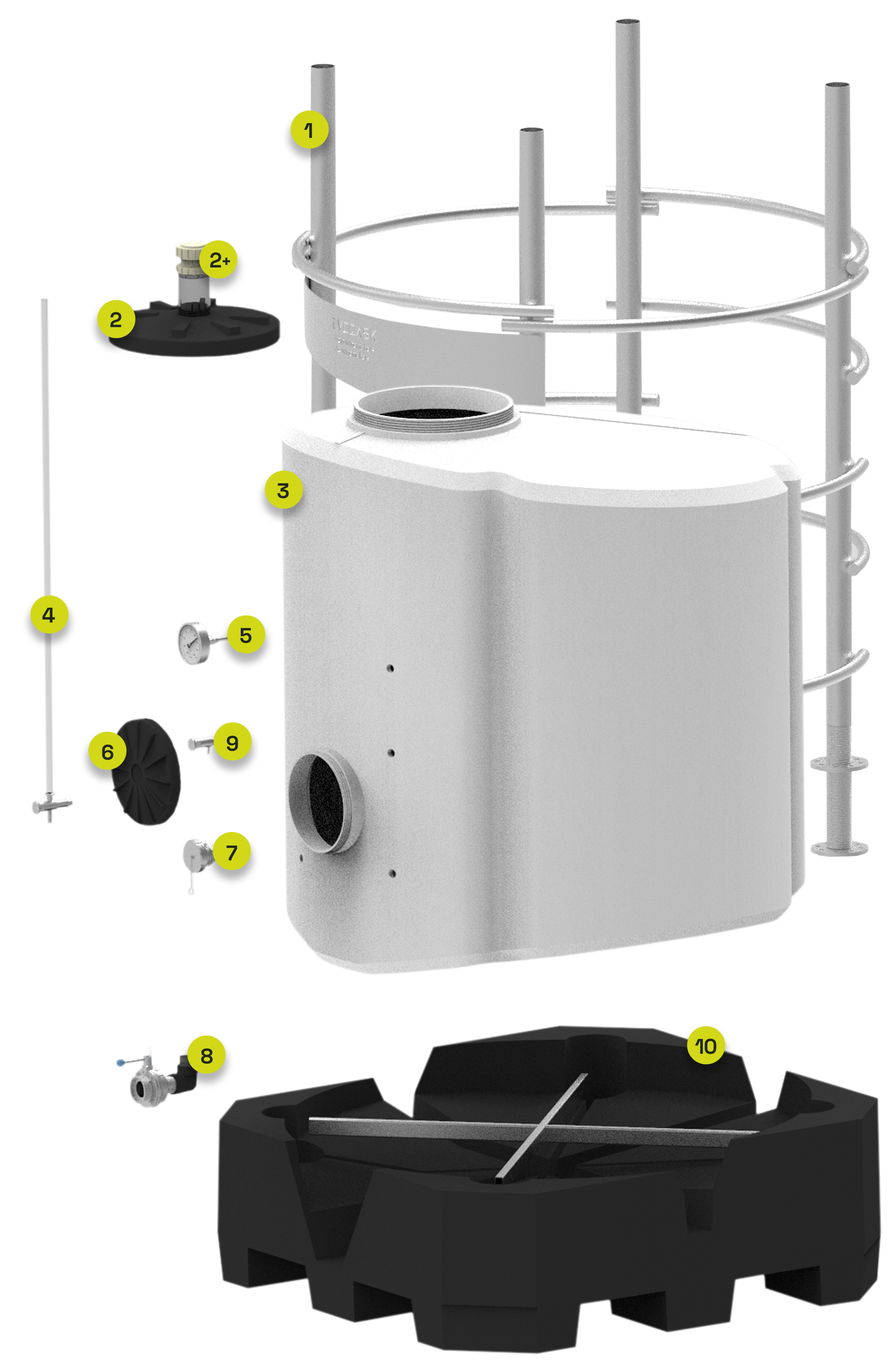

1. Supporting frame

2. Lid

2+. Pressure valve

3. Wine tank

4. Level indicator

5. Thermometer

6. Manhole lid

7. Racking port

8. Drain port

9. Sample tap

10. Pallet

Our products

Model 6 sur lie

600 liter

Model 6 sur lie R

600 liter

Model 11

1100 liter

Model 11 R

1100 liter

1. Supporting frame 2. Lid 2+. Pressure valve 3. Wine tank 4. Level indicator 5. Thermometer 6. Manhole lid 7. Racking port 8. Drain port 9. Sample tap 10. Pallet

The beginnings...

It all started when we were looking for oxygen-permeable plastic tanks for our winery. We believe in the right plastic because we think it’s the sustainable future. However, we couldn’t find the ideal product for us on the market; it seemed as if the manufacturers didn’t involve the winemakers in the design. The difficult-to-clean shapes of the tanks, poor space utilisation and the fine filter with no access to oxygen were all problems, so in the end we didn’t buy.

Talking to our winemaker colleagues, we saw the need and decided to create our own version. We started to develop an innovative oxygen-permeable tank with European food raw material manufacturers and laboratories in mind, with a focus on excellent space utilisation, stackability and unique shape. Our engineers received positive feedback from professional focus groups from the very first versions, and we used state-of-the-art tools such as SolidWorks and SolidEdge in the design process.

It was a lot of work, with unexpected challenges, but the end result is something we are genuinely happy to use.

EvoCask: Sustainable and Cost Effective Wine Container

- Lower costs: designed for the 21st century, EvoCask wine casks are significantly cheaper than oak casks due to their professional production technology. EvoCask containers can be used for up to 30-50 years, compared to oak barrels, which are usually only used for 2-5 years before they need to be replaced.

- Controlled oxygen transmission: thanks to their special eco-composite material, EvoCask tanks are able to transmit oxygen at a controlled rate, which allows the same wine maturation as oak barrels.

- Environmentally friendly solution: thanks to their eco-composite material, EvoCask wine containers can be recycled at the end of their life, reducing their environmental impact. ESG for wineries Lower carbon footprint.

- Greater flexibility and versatility More wine making: EvoCask tanks do not add any flavour to the wine, so winemakers have full control over the wine’s flavour using other methods, such as oak chips or alternative barrels.

- Easier maintenance: cleaning and maintenance of EvoCask containers is much easier and less costly than oak containers, which require regular care and special treatment.

- Hygiene and safety Improved hygiene: EvoCask containers are non-porous, which means they are less prone to the build-up of dirt and microorganisms, unlike oak containers, which can often harbour mould and other contaminants.

- Safety: the material of EvoCask containers does not react with wine, so there is no risk of undesirable chemical reactions that can occur with wood.

- Use of space Compact and lightweight: EvoCask containers are generally lighter and take up less space than traditional wooden barrels, which is particularly useful for smaller wineries or cellars where space optimisation is critical. These benefits all contribute to the increasing popularity of oxygen-permeable plastic tanks like EvoCask in modern wineries, where cost-effectiveness, sustainability and winemaking versatility are paramount.

EvoCask ESG

Environmental, Social, and Governance

The use of the EvoCask wine container offers significant benefits in terms of ESG (Environmental, Social, and Governance) indicators for wine companies – especially for larger wine distributors that are already ESG committed. The EU ESG extension will gradually become a mandatory documentation aspect for all vendors and distributors. Criteria are playing an increasingly important role in the way companies operate today, as investors and consumers increasingly expect sustainable and responsible business practices. The use of EvoCask containers offers many of these sustainability benefits.

Details

1. Environmental Benefits

- Reduced deforestation: EvoCask containers can be used for up to 30-50 years, compared to oak containers, which have a lifespan of only 2-5 years. This means that using a single EvoCask container can replace up to 6-10 oak barrels over its lifetime. Fewer oak trees need to be felled, contributing to forest conservation and biodiversity.

- Reduced carbon emissions: the production and transport of oak barrels requires significant amounts of energy and resources, while the production and transport of EvoCask containers consumes less energy. This helps to reduce the carbon footprint of wineries, which has a positive impact on the fight against global warming.

- Recyclability: EvoCask containers can be made from recycled plastic and can be reprocessed at the end of their life, minimising waste generation and environmental impact.

2. Social Impacts

- Promoting sustainability practices: by using longer-lasting and environmentally friendly EvoCask containers, wineries can promote sustainability practices in the industry, which can increase environmental awareness in society.

- Social responsibility: It is important for wineries to make decisions that take into account future generations. Using EvoCask can help companies to make a positive social impact by using more sustainable production methods.

3. Governance Benefits

- Improving sustainability reporting: ESG aspects are now part of corporate reporting. The use of EvoCask containers can positively impact sustainability reporting, improving a company’s ESG metrics, which can make the company more attractive to investors.

Risk reduction: durable and sustainable products such as EvoCask can reduce long-term risks, such as fluctuations in raw material prices or tightening environmental regulations.

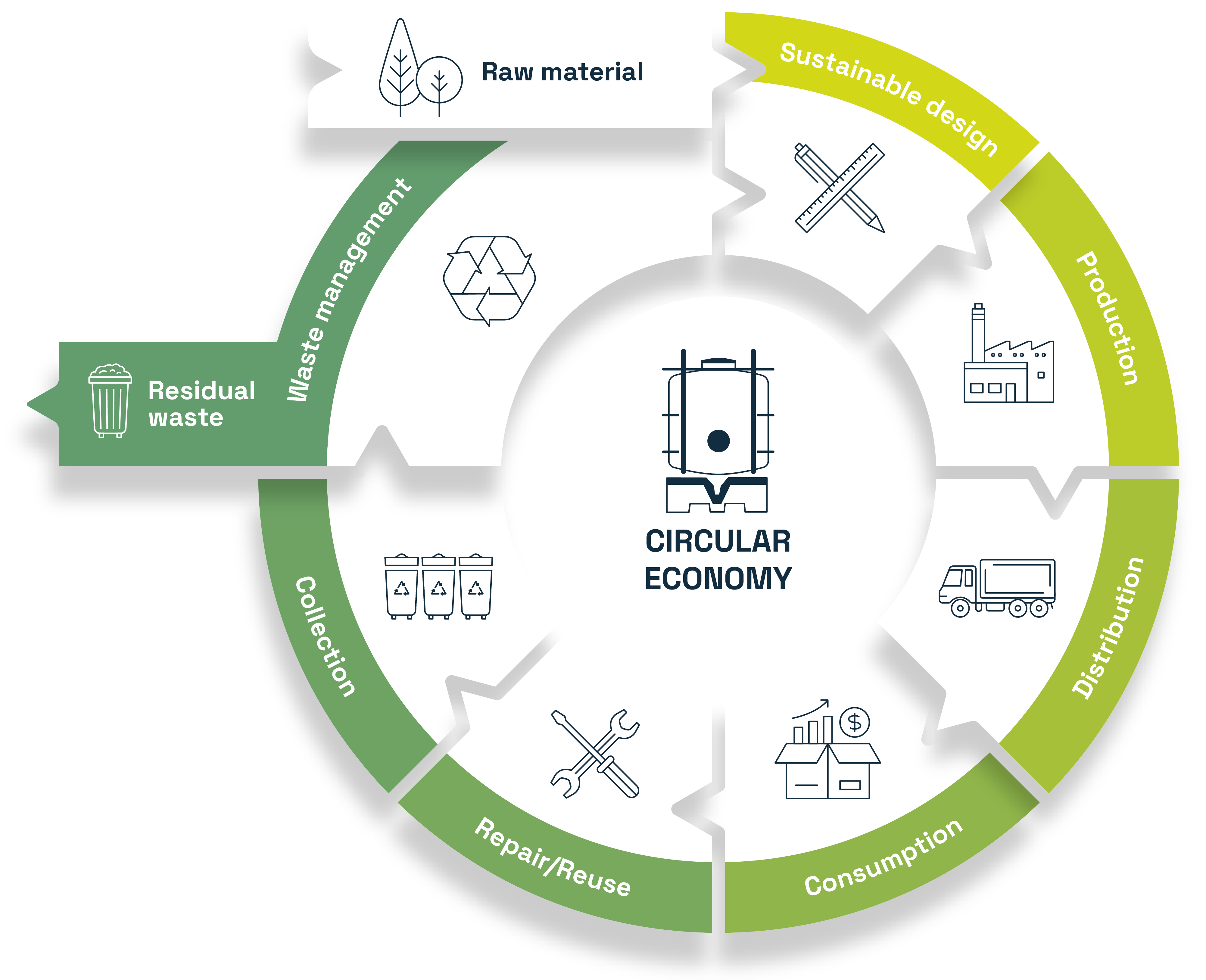

EvoCask for a circular economy

Action plan towards a sustainable future

EvoCask is committed to sustainable development and environmental protection, as reflected in the EU’s Circular Economy Action Plan, which aims to jointly promote a circular economy in Europe.The main goal is to make products have a longer life in the economic cycle, so that we minimise waste and maximise resource efficiency, while reducing the carbon footprint and cost of transport.

Details

Key Objectives of the Action Plan

What is a circular economy, definition and principles?

The circular economy is a sustainable economic system that aims to keep materials and products in circulation for as long as possible. The aim is to minimise waste and use resources efficiently.

Principles and functioning of the circular economy

The circular economy is based on the principle of reduce, reuse, recycle. For industrial production, this means

- Reduction = reducing material consumption and waste production: in polymer technology, for example, this means producing fewer new polymers and using recycled materials instead.

- Reuse = extending the life of products through repair and reuse: plastic products can be designed to be easier to repair or reuse through innovative design approaches.

- Recycling = returning materials to the manufacturing process: the development of recycling processes for polymers is central here, so that materials can be reused after the first use phase.

Products are designed to be durable and easy to repair or recycle. Materials are used efficiently and waste is minimised.

CO2 savings are variable, with carbon reductions of up to 30-90% achieved by recycling polymers compared to the production of new raw materials.

Why is a circular economy so important?

The circular economy is particularly important for polymer technology in order to combat increasing resource consumption and pollution. By implementing circular processes, we have the opportunity to develop sustainable products that are both ecologically and economically beneficial. Through circular processes, companies can reduce their environmental footprint while increasing their efficiency. Efficient recycling processes and the reuse of polymers can make a significant contribution to conserving natural resources and reducing waste.

1. Product Design and Production

Sustainable product design is at the heart of the circular economy. EvoCask’s action plan promotes the design of durable, repairable and recyclable products that not only have a longer life span, but also reduce the demand for new raw materials. This means products stay in the economy for longer, reducing waste.

2. Strengthening the Consumer Role

Consumers play a key role in creating a circular economy. EvoCask’s action plan encourages consumers to make more sustainable choices, such as choosing more durable, recyclable products, thus supporting the circular economy and reducing waste.

3. Waste Management Development

Improving the efficiency of waste collection and recycling is essential for a circular economy. EvoCask aims to facilitate the recovery of valuable materials and their return to the production cycle, thereby reducing the need to extract new raw materials.

4. Supporting the Secondary Raw Materials Market

Developing the market for recycled materials is a priority in EvoCask’s Circular Economy Action Plan. The use of secondary raw materials reduces the demand on natural resources and contributes to the sustainability of the economy.

5. Industrial Measures

EvoCask sets out concrete actions for industries such as plastics, construction, textiles and electronics. These industries are largely responsible for waste production, so the introduction of sustainability guidelines is essential to protect the environment.

Its importance for polymer technology

EvoCask’s Circular Economy Action Plan encourages the development and use of recycling technologies. This will reduce the need to produce new polymers, promoting the use of more sustainable materials and the development of innovative solutions that not only benefit the environment but also give companies a competitive advantage.

The Action Plan is in line with the EU’s objectives to ensure that economic activities are sustainable in the long term, reducing environmental pressures and supporting the circular economy.

1. Product design and manufacturing

Sustainable product design is part of the circular economy, resulting in more durable, repairable and recyclable products, reducing the demand for new raw materials.

2. The role of consumers

Consumers can help create a green economy by choosing sustainable products.

3. Improving waste management

Improving waste collection and recycling is important to recover valuable materials and reduce environmental impacts.

4. Supporting the market for secondary raw materials

Expanding the market for recycled materials reduces the need to extract natural resources.

5. Sector-specific measures

The EU is introducing targeted measures to promote sustainability in industries such as plastics, construction, textiles and electronics.